The Future of Rubber Granules in Recycling

- Jack Wrytr

- Oct 1, 2025

- 3 min read

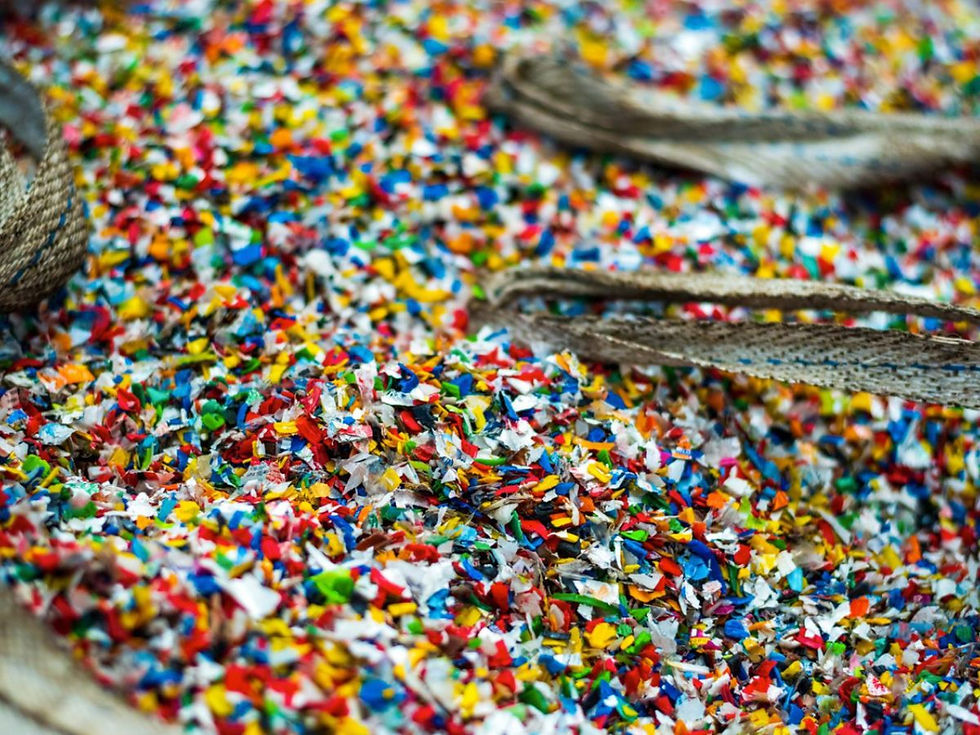

The recycling industry is at a pivotal moment, and rubber granules are playing a key role. More and more people than ever are concerned about the environment. This in-depth look examines how these small particles are changing the way we recycle.

Understanding Rubber Granules and Their Environmental Impact

Rubber granules are tiny particles created from breaking down old rubber. The global market for recycling rubber is expected to hit $200 billion by 2031. This rapid growth demonstrates the seriousness with which people are taking care of the environment.

Millions of tons of waste get diverted from landfills every year. Companies like Sneaker Impact are leading the way with over 15.75 million pairs of shoes recycled and more than 128 million kilograms of CO2e kept out of landfills. This approach demonstrates that recycling can encompass a wide range of rubber products.

Market Dynamics Driving Rubber Granules Innovation

Current Market Trends

The market for reclaimed rubber is projected to reach $2.55 billion by 2033, growing at a compound annual growth rate (CAGR) of 7.4%. North America is the leader in this sector. This is mainly due to strict environmental laws and a growing public focus on sustainability.

The Asia Pacific region is expected to hit over 8% by 2032. What's driving this growth is the rising demand for alternatives to virgin materials. Industries are looking for affordable and sustainable options.

Technological Advancements in Rubber Granules Processing

New recycling technologies have made an enormous difference. By using advanced mechanical grinding techniques, manufacturers can produce granules in precise sizes from 0.5mm to 4mm. Another process, called cryogenic processing, involves freezing rubber with liquid nitrogen before grinding it.

Chemical devulcanization works by breaking down sulfur bonds in vulcanized rubber. This innovation opens up new uses for recycled rubber granules, making them more valuable.

Diverse Applications of Rubber Granules

Sports Surfaces and Playground Safety

Rubber granules have made an enormous difference. SBR granules provide athletic fields and playgrounds with the elasticity they need, thereby reducing the risk of injuries. EPDM granules are great at withstanding the elements, maintaining their performance no matter the weather.

Tire-derived rubber is composed of approximately 45% natural and synthetic rubber, 13% steel, and 14% textiles, making it a highly resource-rich material.

Industrial and Construction Applications

Rubber granules play a big part in more than just sports fields. They're also used in construction and manufacturing projects. For instance, they're mixed into asphalt to make roads long-lasting.

Additionally, they serve as insulation and contribute to soundproofing. The auto industry uses recycled rubber granules to make various parts and noise-reducing systems.

Environmental Benefits and Sustainability

The benefits of recycling rubber granules go way beyond reducing waste. For every ton of recycled rubber, we reduce CO2 emissions by approximately 2,000 pounds. Companies like Sneaker Impact not only keep waste out of landfills, but also create jobs for over 5,000 small business owners.

Recycling rubber granules helps conserve petroleum by reducing the amount of fossil fuels required. Extending the life of rubber materials also reduces the need to extract more raw materials and lessens the environmental harm.

Regulatory Landscape and Future Challenges

Emerging Regulations

The European Union is set to ban certain kinds of rubber granule infill on artificial sports fields. This transition provides facility managers with time to explore other options. These rules are driving innovation in making rubber granules safer and more environmentally friendly.

Addressing Safety Concerns

Recent studies have examined the safety of rubber granules closely. Manufacturers are now employing rigorous testing protocols to ensure their products meet stringent standards. Third-party certifications add transparency and help consumers trust recycled rubber granules.

The Future Outlook for Rubber Granules

The outlook for rubber granules in recycling is really looking up. Advances in materials science continually improve product quality. 'Smart' recycling technologies that utilize AI are streamlining the sorting and processing process.

Circular economy principles are gaining traction, with leading corporations setting ambitious targets. Companies like Sneaker Impact illustrate how focused recycling initiatives can scale successfully, offering models for enhancing rubber granules.

Advances in 3D printing and nanotechnology are poised to create new opportunities for rubber granules. As the field evolves, rubber granules are expected to shift from basic industrial ingredients to high-end materials.

Key Takeaway

The future of rubber granules is not just about environmental stewardship, but also about driving innovation. With predictions showing growth of over 10%, increasing government support, and more applications, rubber granules are poised to become a key component of sustainable development.

As we head into the next decade, these tiny bits are poised to play an increasingly important role in building an economy that benefits everyone.

Comments